Hierarchical registration method for surface quality inspection of long products

Abstract

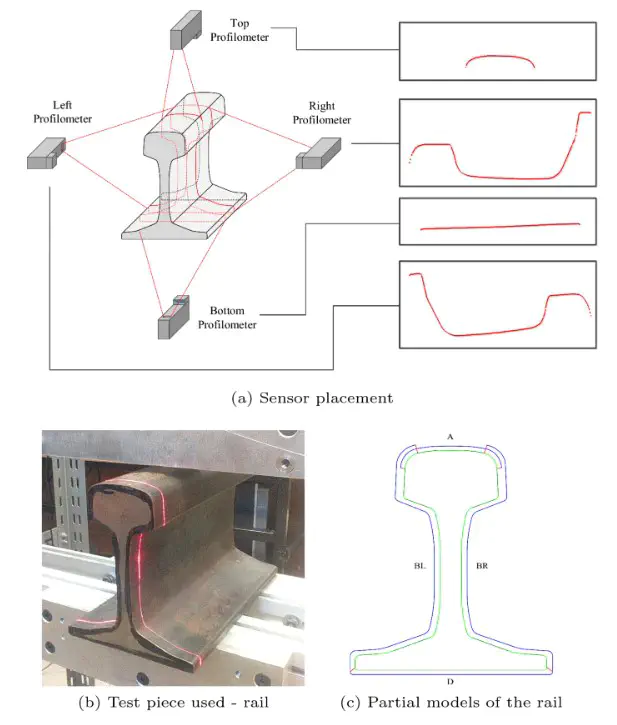

Manufacturing industry often uses 3D scanning technologies to inspect their products. Some of these techniques produce a point cloud that represent a section of the manufactured product. The clouds must be aligned to the model of the product in order to check its quality. Current registration methods are usually affected by dimensional problems or volumetric anomalies. This paper proposes a new method for the registration process aligning the cloud to the model in several steps. The first step is the state-of-the-art method. The second step uses the information acquired in the first one to perform a fine registration in order to not being affected by dimensional defects or little miss alignments in the previous step providing a huge improvement in the measurement of surface defects. In this paper, several techniques are proposed in order to provide a set of tools that the final users can tune to fit their needs. The whole procedure of registration can be run in real-time conditions using the sampling and caching strategies proposed. The methods proposed are tested over more than 10,000 profiles of a rail proving they successfully align the cloud and the model providing better results in the measurement of surface defects.